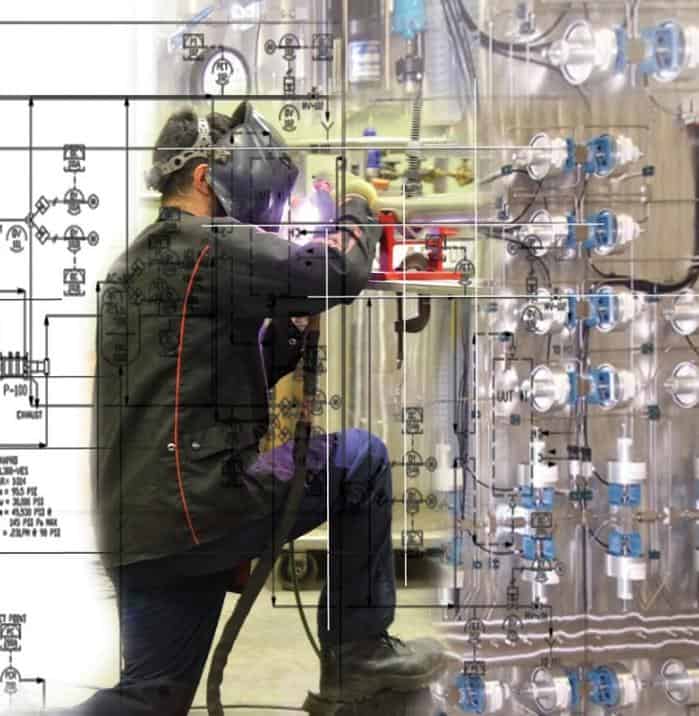

Welcome to Optimation: Your Partner in American-Made Industrial Project Solutions

Here at Optimation, we are a proud industry leader in American Made design and engineering solutions. By striving towards providing engineering design and development solutions of the highest quality, we offer a wide variety of industrial project innovations. Optimation is the perfect partner for any business looking to reshape the industrial landscape in the United States, thanks to our commitment to American Manufacturing and innovative approach to industrial project management.

About UsOur Expertise

See real success stories from clients leveraging engineering services, skilled trades services, or a complete, turnkey solution.

View ProjectsWhy Optimation?

Multi-Discipline Expertise

At Optimation, we pride ourselves on our multi-discipline expertise. From process engineering to controls, from fabrication to installation and integration, we are your sole source supplier for your project. Our talented team of engineers, designers, and project managers work collaboratively to ensure a seamless and successful outcome for your industrial project.

Technology Agnostic

We are committed to developing the right solution for you. We do not promote any one type of technology as a firm that is technology-agnostic. Instead, we assist you in making the right decision for your plant and unique situation, ensuring that your industrial project takes advantage of the most recent innovations and industry best practices.

Quality Focus

The employees of Optimation are committed to building lasting client relationships by providing consistently superior services. Our dedication to quality, innovation, and customer satisfaction ensures that your industrial project is executed with the highest standards of excellence.

Concept to Completion

Whether you have an idea, a new process, a pilot plant, or a prototype, Optimation helps you get to the next level through to full-scale production. Our comprehensive industrial project management services cover every aspect of your project, from initial concepts to final implementation, ensuring a smooth transition and a successful outcome.

Featured Case Studies By Industry

See real success stories from our clients, GE, Byogy Renewables Inc, and more.

Why Optimation?

Multi-Discipline Expertise

From process engineering to controls, from fabrication to installation and integration, we are your sole source supplier for your project.

Technology Agnostic

We do not promote any one type of technology as a firm that is technology-agnostic. Instead, we assist you in making the right decision for your plant and unique situation

QUALITY FOCUS

The employees of Optimation are committed to building lasting client relationships by providing consistently superior services. Our dedication to quality, innovation, and customer satisfaction ensures that your industrial project is executed with the highest standards of excellence.

CONCEPT TO COMPLETION

Whether you have an idea, a new process, a pilot plant, or a prototype, Optimation helps you get to the next level through to full-scale production.

Optimation’s services represent a valuable extension of our own, internal engineering resources, bringing particular focus to our automation needs.

Unwavering Commitment To American Manufacturing

Interested In Working With Us? Let’s Connect.

Choose Optimation for your next industrial project and experience the difference our multi-discipline expertise, technology agnosticism, and quality focus can make.