3D printing is a type of additive manufacturing that creates products in a new, more efficient way. In recent years, it has had a major impact on the manufacturing industry. One area where additive manufacturing excels is the creation of prototypes. In the past, companies had to find the right partner to produce a prototype on their behalf. Depending on the component being produced, several machining techniques that need time, skilled labor, and secondary machining might be required.

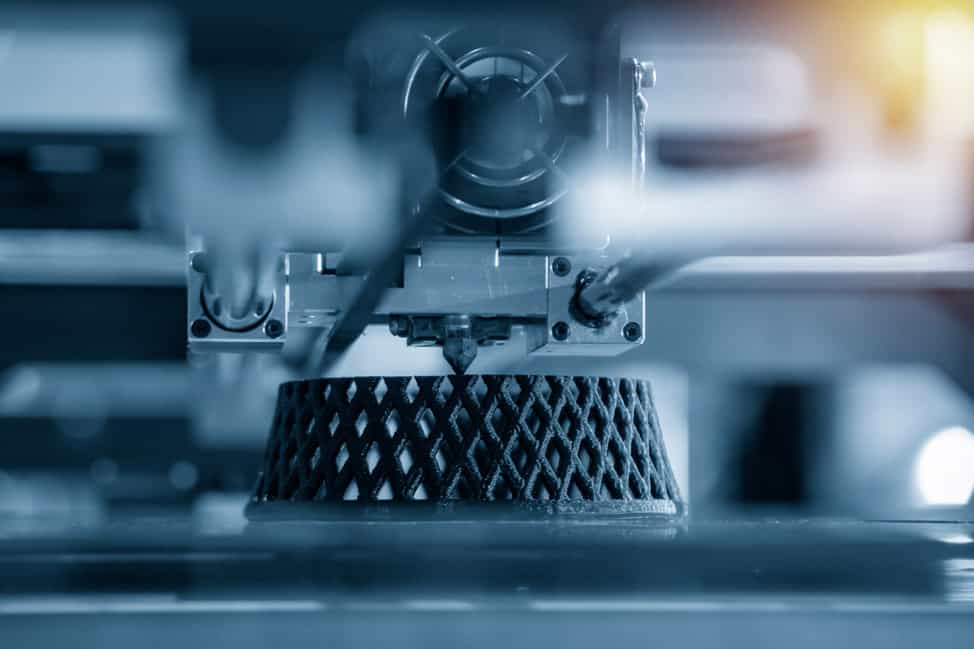

Today, however, companies of all sizes can easily incorporate 3D printing technology into their facility and produce prototypes quickly and cost-effectively. Many 3D printers are easy to set up and operate, with both small and large-scale options available to meet the needs of both smaller companies as well as large-scale manufacturers with high-end needs. The latest additive manufacturing technology can print plastics, metals, and many other materials, building components from the bottom up, layer by layer. Through autonomous operation, they quickly produce parts with complex geometries and internal structures. As an increasing number of companies begin utilizing this technology, it becomes more important than ever for manufacturers to adopt these innovations to remain competitive.