Process Engineering and Design

Process Engineering

Optimation’s process engineers solve problems for clients in the chemical, pharmaceutical, renewable energy, and oil and gas industries. You may be a startup company looking for help with definition of the production process required for your new product, or you may be looking to improve energy usage, product quality or throughput on an existing production line. Our multi-disciplined team solves these problems and more with ingenuity and efficiency.

New Process Definition

Firms originating new, unique manufacturing processes choose Optimation as their partner in developing the best processes to manufacture their products. Our team works closely with you to understand your quality and production goals. We develop a functional specification and conceptual design based on our assessment and your feedback, customized for your unique product.

Already have an existing concept or pilot scale production? Our process engineers can evaluate your process for full-scale manufacturability, and complete engineering and design for full scale production.

Process Design Improvement and Troubleshooting

You have an existing production process in place – but there’s room for improvement. Optimation’s process engineering team can come up with solutions to:

- Expand manufacturing capacity

- Optimize product quality

- Increase manufacturing throughput

- Reduce energy usage

- Drive out product variability

- Evaluate production data to uncover improvement opportunities

- Simplify the production process

Process Development, Scale-Up and Optimization

Process Development

Optimation develops innovative manufacturing processes. Our team can work with a developer and turn their process concept or patented process into an operational unit. Optimation eases the pressure of a new process or scale-up bringing the expertise of our process, mechanical, E/I, chemical and controls engineers and designers to the table, helping you with process verification, design, production instrumentation and scale-up. We specialize in development for first-of-a-kind production processes.

Process Scale-Up

We bridge the gap from your pilot process to scale-up and full manufacturing capability. Engineering, designing and building a full-scale process tailored to your specs. This can involve a re-design of your process, utilizing custom equipment and/or off-the-shelf components. We aren’t equipment suppliers; we engineer an optimized production process that meets your requirements.

Process Optimization

Manufacturers across different industries share the same fundamental manufacturing challenges. They are concerned about maximizing yield and product quality, minimizing energy consumption, and of run-to-run variability at each site and across different production plants. Dealing with multiple plant operations can be challenging because of differences in systems, processes, business definitions, and equipment.

Imagine being able to:

- Display increased process variability before products are negatively affected.

- Summarize massive and complex data to an actionable data subset.

- Improve quality and reduce waste.

If process variability is worth monitoring, it needs to be measured.

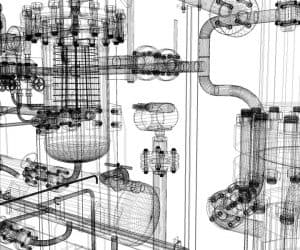

Process Design

Optimation specializes in process design services, including PFD and P&ID development, for batch and continuous systems, as well as discrete processes. Our process designers use AutoCAD and Inventor to create 2D and 3D models for projects in the chemical, pharmaceutical, food and beverage, oil and gas, and film industries.

Skid Design

Use our expertise in custom skid design and fabrication services for a variety of industries. Previous skid design and fabrication projects have been provided for clients in the chemical, food and beverage, oil and gas, and consumer products and manufacturing industries. Engage us to work with your concept, develop the design, and create final release drawings and specifications that will meet all requirements of your project. Designs can be developed independently or in close coordination with your team.

Plant/Facility Layout

Use Optimation’s process design services for new plant layout, or equipment upgrades. Our process designers specialize in facility layout and system integration, packaging and fitting in space. Our designs include a multidiscipline approach including process design, material handling, mechanical design, machine design, structural design, electrical design and controls engineering.

Piping Design

- Knowledge of piping materials applications for your chemistry

- Selection of optimal joining techniques

- 3D rendering for pipe routing

- Pipe specifications determined based on needed working pressures and flows

- Ability to incorporate cleaning technologies (for example, CIP)

- Incorporation of controls elements (valves, flow controls, pressure regulators, gauges, sensors) to match your process conditions

- Sanitary considerations in pipe construction and components

- Design for Manufacturability

Air Systems Design

Use our air system design services, including process air systems, building air systems including heating, cooling and humidification control. We also design air systems for clean rooms and clean manufacturing applications.

Turnkey Process Design/Build Services

One of the advantages to our clients is the ability to work with one service provider throughout the life of the project. Optimation offers engineering, design and build services for your industrial process, as well as fabrication, installation, system integration, maintenance and controls support services.

Our ability to build concurrently with design, paired with the synergy and efficiency of our multi-disciplined team, saves you time and money on your project.